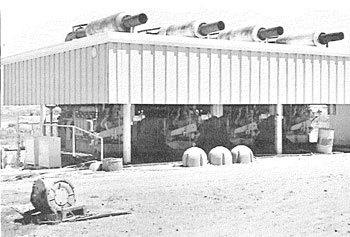

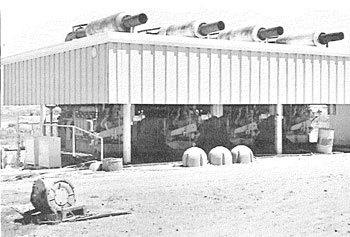

Natural gas powered irrigation pumps.

Natural gas powered irrigation pumps.

The electric motors that powered the pumps were among the largest that had been put into use in Idaho. They were 1,250 horsepower each. The pumps were manufactured by the Worthington Pump Company and were capable of developing the 450 pounds of pressure necessary to force the water up to the 725-foot elevation. The penstock was thirty-six inch steel pipe through which 30,700 gallons of water per minute could be pumped to the distribution system on the plateau. The new concept of the Sailor Creek project was the substitution of pressurized pipe lines to distribute the water to the fields instead of open ditches. Completely underground, the system of welded and coupled pipes consisted of nearly 65 miles of main and lateral lines ranging from 36-inch penstock to three-inch laterals. Sailor Creek initially brought in 3,750 acres of new land and again a high-lift project became the enthusiastic topic of conversation among Idaho potato growers and land developers all over the state.

When Sailor Creek became a reality, feverish activity in the development of additional desert entry projects constituted a veritable land rush. Sailor Creek was quickly followed by the Billy Rio Ranch, the Cottonwood Canal project, the Indian Hills project, and Black Mesa.

Indian Hills had one interesting innovation in that the developers chose to use natural gas as an energy source for pumping water rather than electricity. Natural gas was burned in huge internal combustion engines that powered the pumps and the gas-distribution company became a competitor of the Idaho Power Company in the marketing of an excess summer pipeline capacity of natural gas.

The Indian Hills project seemed to carry an omen of ill fortune from the beginning that virtually ended the desert entry reclamation activities by causing the Bureau of Land Management to put a freeze on granting desert entry claims.

When the pipeline and pumping station at Indian Hills was completed, the engines were started for the first test. The water was pumped into the pipeline and up to the mesa above. At that point, the project engineers were satisfied that the system would work and shut off the gas engines. For some unknown reason, the system designers had not put check valves in the pipelines and as the water in the penstock ran back down to the level of the Snake River, the great weight of the rushing water turned the impellers in the pumps backward, also running the natural-gas engines backward and creating extensive damage. Indian Hills also proved to have water-distribution problems: canals had been designed without sufficient checks and water proved to be difficult to control with flooding in some areas to a depth of three and four feet.

Natural gas powered irrigation pumps.

Natural gas powered irrigation pumps.